Step-by-Step Guide on Replacing Chainsaw Spark Plugs

Chainsaws are powerful tools, but when they fail to start or run smoothly, the spark plug might be the culprit. This guide will outline the critical steps for replacing your chainsaw’s spark plug, including how to identify when it needs changing, what tools you’ll require, and detailed instructions for the replacement process. By following these steps, you can enhance your chainsaw’s performance and ensure it operates efficiently, ultimately saving time and money on repairs. Whether you’re a seasoned gardener or a novice, this guide will help you tackle spark plug issues with confidence.

Key Takeaways

- A faulty spark plug can lead to poor chainsaw performance and increased fuel consumption

- Regular inspection and maintenance of the spark plug are essential for optimal chainsaw operation

- High-quality spark plugs can improve engine performance and reduce the need for frequent replacements

- Proper gapping and torque of the spark plug are crucial for preventing misfires and engine damage

- Scheduling routine checks can help identify wear and prolong the lifespan of the chainsaw

Understanding the Role of the Spark Plug in Your Chainsaw

The spark plug plays a crucial role in chainsaw operation by igniting the fuel-air mixture in the cylinder, ensuring smooth performance. A faulty spark plug can lead to poor engine start, misfires, and decreased power—often linked to issues with the ignition coil or valve. This section will explore how the spark plug influences chainsaw efficiency and the effects of neglecting its maintenance.

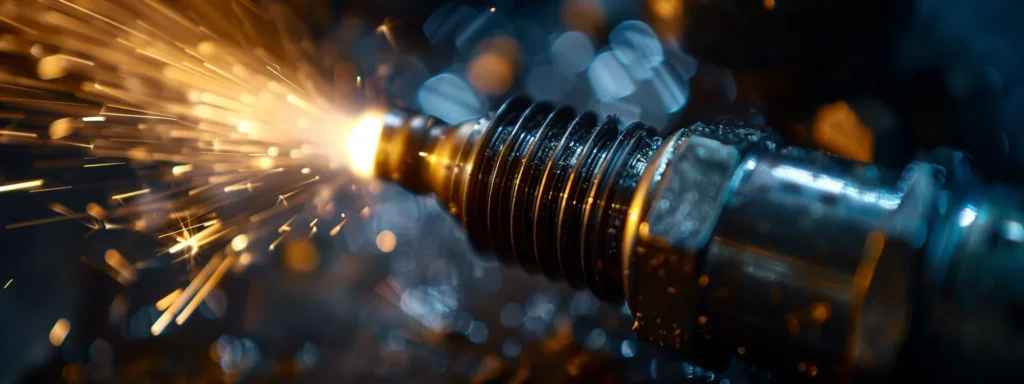

How the Spark Plug Influences Chainsaw Operation

The spark plug plays a vital role in chainsaw operation, functioning as the component that ignites the fuel-air mixture within the engine’s cylinder. A properly working spark plug creates a spark that travels across the electrode, initiating combustion. This process is essential for the chainsaw’s performance; without it, the engine cannot run efficiently.

When replacing spark plugs, it is crucial to choose high-quality parts that fit the chainsaw model. A worn or faulty spark plug can lead to issues such as hard starting and poor fuel efficiency, increasing the likelihood of a frustrating auto repair scenario. Regular maintenance, including inspections of the spark plug, ensures that the engine runs smoothly and reduces the risk of more significant problems down the line.

Neglecting the spark plug can affect overall chainsaw performance, leading to reduced power and increased fuel consumption. When the electrode on the spark plug deteriorates, it may not generate an adequate spark, resulting in misfires and inconsistent operation. Understanding how to maintain and replace spark plugs is essential for any chainsaw user to maintain optimal performance and extend the lifespan of their tool.

Effects of a Faulty Spark Plug on Performance

A faulty spark plug can significantly impact the performance of a chainsaw. When the spark plug fails to ignite the fuel-air mixture properly, it can trigger the check engine light, indicating an issue within the ignition system. This often leads to hard starting, decreased power, and increased fuel consumption, which can frustrate users as they struggle to get their chainsaw running smoothly.

Neglecting the spark plug can also result in mechanical problems that may require further inspection, such as examining the rocker cover for leaks. If a spark plug fails, it may lead to engine misfires, which not only affect performance but can also cause wear and tear on other components within the engine. Addressing these issues quickly is essential to prevent more extensive damage and costly repairs.

Regular maintenance, such as checking the spark plug for wear, is crucial for optimal chainsaw operation. Ensuring that the spark plug is properly torqued according to manufacturer specifications helps maintain engine performance and longevity. Users should prioritize replacing a faulty spark plug to restore efficiency and mitigate the risk of system failure, keeping their chainsaw in peak condition for all cutting tasks.

- A faulty spark plug can trigger the check engine light.

- Engine misfires can lead to wear on other components.

- Regular maintenance ensures the chain saw operates efficiently.

Identifying When Your Chainsaw Spark Plug Needs Replacement

Common signs of a worn-out spark plug include difficulty starting, misfires, and a decrease in engine power. Inspecting the spark plug for damage, such as oil deposits or wear, is essential to determine if a replacement is necessary. Understanding these indicators will aid in maintaining optimal chainsaw performance and prolonging the life of components like the catalytic converter.

Common Signs of a Worn-Out Spark Plug

One of the most apparent signs that a chainsaw spark plug needs replacement is difficulty starting the engine. When the spark plug is worn out, it may fail to provide the necessary high voltage needed to ignite the fuel-air mixture effectively. This can often lead to frustration for the user, as repeated attempts to start the chainsaw may yield little to no results.

Another indicator of a failing spark plug is engine misfire while operating the chainsaw. If the spark plug wires or wire connections are faulty, this can disrupt the ignition process, causing the throttle to respond inconsistently. Users may notice a sudden decrease in power or a rough idle, hinting that it’s time for a thorough inspection of the spark plug.

Finally, checking for signs of physical wear on the spark plug itself can reveal significant issues. If the plug shows excessive oil deposits, corrosion, or has a burnt electrode, it’s a clear signal that replacement is necessary. Monitoring these factors helps maintain the chainsaw’s overall efficiency and reduces potential repair costs, ensuring consistent performance during use:

- Difficulty starting the engine.

- Engine misfires during operation.

- Visible signs of wear on the spark plug.

Inspecting the Spark Plug for Damage

Inspecting the spark plug for damage is a crucial step in maintaining a chainsaw. Users should first ensure they have the right tools handy, including a wrench and screwdriver, to access the spark plug. This inspection allows for an early detection of potential issues that could affect engine efficiency.

During the inspection, users should check for visible signs of wear such as corrosion, oil deposits, or a burnt electrode. A spark plug showing these signs may fail to ignite the fuel-air mixture correctly, leading to performance issues. Ensuring the electrical connector is secure and free of damage is also important, as a loose connection can disrupt the ignition process.

For a thorough assessment, it’s advisable to remove the spark plug and examine it closely. Checking the gap and ensuring it meets manufacturer specifications is key to optimal operation. If any abnormalities are detected, replacing the spark plug promptly will enhance overall chainsaw performance, avoiding potential frustrations during use:

- Gather necessary tools, including a wrench and screwdriver.

- Inspect for signs of wear such as corrosion and oil deposits.

- Check the electrical connector for secure connections.

- Remove the spark plug and assess the gap against specifications.

Assembling the Necessary Tools and Replacement Parts

Before replacing the spark plug in a chainsaw, it is essential to gather the required tools and select the correct replacement parts. This section will cover the tools needed for the process, ensuring a smooth replacement. Additionally, it will discuss the importance of choosing the right spark plug, specifically highlighting the benefits of iridium options for optimal performance.

Tools Required for Changing a Chainsaw Spark Plug

When changing a chainsaw spark plug, having the right tools is essential for a successful replacement. A socket wrench is typically necessary to loosen and remove the old spark plug from the engine. Additionally, a torque wrench ensures that the new spark plug is tightened to the manufacturer’s specifications, which helps maintain optimal performance and prevents potential engine damage.

It’s also important to have a spark plug gap tool on hand. This tool measures the gap between the electrodes of the spark plug, ensuring it meets the required specifications before installation. Proper gapping of the spark plug is crucial, as an incorrect gap can lead to misfires or difficulty starting the engine.

Lastly, a pair of pliers can be useful to safely handle the spark plug when removing or installing it. This tool aids in gripping the plug firmly without causing damage to the electrodes. Ensuring all tools are readily available before starting the process promotes efficiency and minimizes the risk of interruptions during the spark plug replacement in a chainsaw.

Choosing the Correct Spark Plug for Your Chainsaw

Choosing the correct spark plug for a chainsaw is crucial for maintaining optimal performance and ensuring the engine runs smoothly. Users should always refer to the chainsaw’s owner manual since it provides specific information about the right spark plug type and manufacturer recommendations. Selecting the correct spark plug prevents starting issues and promotes efficient fuel use.

Many chainsaw models benefit from high-quality spark plugs, such as those made from iridium. These spark plugs offer better conductivity and longevity compared to standard options, resulting in improved engine performance and fuel efficiency. Investing in the right spark plug not only enhances chainsaw capability but also reduces the frequency of replacements, saving users time and money.

It is essential to consider the spark plug’s heat range as well, which affects its operating temperature. A spark plug that runs too hot or too cold can lead to engine problems, such as overheating or fouling. Understanding the heat range required for the specific chainsaw model helps users avoid potential issues, ensuring reliable performance throughout the tool’s lifespan.

Preparing Your Chainsaw for Spark Plug Replacement

Before replacing the spark plug in a chainsaw, it is essential to ensure safety and prepare the work area. This includes disconnecting the spark plug wire to prevent accidental start-ups and cleaning around the spark plug to avoid debris entering the engine. These initial steps lay the groundwork for a successful and efficient spark plug replacement process.

Ensuring Safety Before Starting Maintenance

Ensuring safety before starting maintenance on a chainsaw is paramount, as it helps prevent accidents and injuries. The first step is to disconnect the spark plug wire, which eliminates the risk of the chainsaw accidentally starting while working. This simple action provides peace of mind for the user, allowing them to focus on the task at hand without worry.

Next, it is advisable to wear appropriate personal protective equipment, such as gloves and safety glasses. These items protect against flying debris and provide grip while handling tools, enhancing the overall safety during the replacement process. Taking these precautions ensures that the focus remains on the task without the distraction of potential hazards.

Lastly, users should prepare a clean work area around the chainsaw. Clearing away any dirt, dust, or debris not only makes for a more efficient working environment but also reduces the chance of contaminants entering the engine when the spark plug is removed. A tidy workspace adds to the overall safety and effectiveness of the maintenance effort, ultimately supporting the longevity of the chainsaw.

Cleaning the Area Around the Spark Plug

Cleaning the area around the spark plug is a crucial step in the spark plug replacement process. This helps prevent debris or dirt from entering the engine, which can lead to potential damage or performance issues. Using a clean cloth or brush, the user should carefully wipe away any excess grime, ensuring a clean working environment for the maintenance task.

Additionally, it’s important to inspect the spark plug hole for any residual debris before removing the old plug. If there is any heavy buildup, using compressed air can effectively clear the area, ensuring that no contaminants are dislodged into the combustion chamber during the replacement process. This attention to detail not only supports the longevity of the engine but also enhances overall performance.

A clean workspace around the spark plug helps facilitate an efficient replacement process. By taking the time to clear away any dirt or grime, users can avoid frustrations that may arise from obstructions while working. This simple yet essential step contributes to smoother maintenance and can ultimately save time and effort in maintaining the chainsaw effectively.

Step-by-Step Instructions for Replacing the Spark Plug

This section outlines the essential steps for replacing a chainsaw spark plug, starting with disconnecting the spark plug lead to ensure safety. It progresses through removing the old spark plug and installing the new one correctly, followed by reattaching the spark plug lead. Each step is vital to maintain optimal chainsaw performance and ensure long-lasting operation.

Disconnecting the Spark Plug Lead

To start replacing the spark plug in a chainsaw, the first step is to disconnect the spark plug lead. This action is essential for safety, as it prevents the chainsaw from accidentally starting while the user is performing maintenance. Failing to disconnect the lead can lead to serious injuries, so this step must not be overlooked.

When disconnecting the spark plug lead, users should grasp the connector firmly and pull it away from the plug. It is advisable to avoid pulling on the wire itself, as this can cause damage to the ignition system. Ensuring a secure grip on the connector reduces the risk of any accidental tugging during the process, making it easier to detach.

Once the spark plug lead is disconnected, users can safely proceed with the rest of the spark plug replacement process. Taking the time to ensure the lead is correctly detached not only promotes user safety but also facilitates a smooth transition to inspecting and replacing the spark plug itself. Proper preparation at this stage helps prevent complications later on:

- Disconnect the spark plug lead for safety.

- Grip the connector firmly and pull gently.

- Ensure the lead is fully detached before proceeding.

Removing the Old Spark Plug

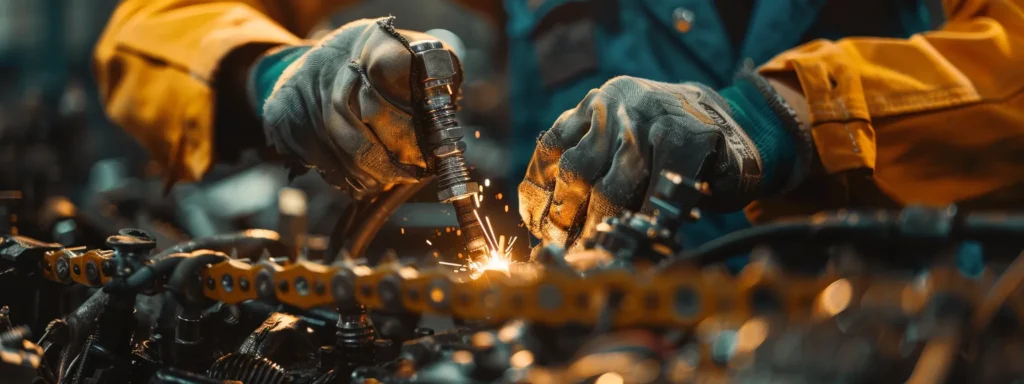

To remove the old spark plug from a chainsaw, users should begin by securing the necessary tools, notably a socket wrench that fits the spark plug size. It is essential to ensure the wrench is fitted correctly to avoid stripping the plug, which can complicate removal. Once the right tool is in hand, users can proceed to loosen the spark plug by turning it counterclockwise, taking care to apply steady pressure without forcing it.

After the spark plug is loosened, it can be lifted from the cylinder head with ease. Users should be cautious during this step, as the plug may be hot if the engine has been recently used. If any resistance is felt while removing the plug, it may be beneficial to clean the area around the base to prevent debris from falling into the engine, which could cause damage.

Once the old spark plug is fully removed, users should inspect it for signs of wear or damage. Any oil deposits, broken ceramic insulator, or burnt electrodes indicate that it needs replacing. This inspection not only aids in confirming the necessity of a new spark plug but also assists in diagnosing underlying issues within the engine, ensuring the chainsaw operates reliably moving forward.

Installing the New Spark Plug Properly

When installing the new spark plug, it is essential to ensure that it is positioned correctly in the cylinder head. Users should gently thread the spark plug by hand to avoid cross-threading, which can cause damage to both the plug and the engine. Taking care during this step helps to ensure a secure fit and optimal performance of the chainsaw.

Once the new spark plug is in place, users should utilise a torque wrench to tighten it according to the specifications provided by the manufacturer. Proper torque is crucial; too tight can cause damage, while too loose can result in potential misfires or leaks. This attention to detail can significantly contribute to the chainsaw’s reliability and longevity.

After securing the spark plug, the electrical connector should be reattached firmly. Ensuring a tight connection eliminates potential ignition issues that could arise from a loose fit. By taking these steps, users can confidently expect smooth operation from their chainsaw, ultimately enhancing their overall cutting experience.

Reattaching the Spark Plug Lead

Reattaching the spark plug lead is a straightforward process that ensures the chainsaw functions optimally. After securely positioning the new spark plug, the lead must be connected back to the spark plug terminal to restore the electrical connection. It is important to press down firmly until hearing a click, indicating that the lead is properly attached, which will prevent starting issues caused by loose connections.

When reattaching the spark plug lead, users should take care to avoid yanking on the wire itself. Instead, they should hold the connector firmly while pushing it down onto the plug. This careful handling prevents damage to both the lead and the ignition system, helping maintain the chainsaw’s reliability and performance over time.

Once the spark plug lead is securely attached, it is advisable to double-check the connection before starting the chainsaw. Ensuring that the lead is fitted snugly can help prevent engine misfires or starting difficulties. This step, though simple, is essential for the smooth operation of the chainsaw, allowing users to confidently proceed with their cutting tasks without unnecessary complications.

Post-Replacement Checks and Maintenance Advice

After replacing the spark plug in a chainsaw, it is crucial to conduct thorough post-replacement checks to ensure optimal performance. This section will cover how to test the chainsaw effectively after replacement, offering tips for prolonging spark plug life to avoid frequent replacements, and emphasising the importance of scheduling regular maintenance. By following these guidelines, users can enhance the reliability and efficiency of their chainsaw.

Testing the Chainsaw After Replacement

After replacing the spark plug, it is essential to perform a series of tests to ensure the chainsaw operates smoothly. Users should start by reconnecting the spark plug lead securely and attempting to start the engine. A successful ignition indicates proper installation and functionality of the new spark plug, ensuring the chainsaw is ready for use.

Next, a brief run of the chainsaw helps verify its performance under load. Users should observe how the engine responds during cutting tasks; it should run smoothly without misfires or stalling. If the chainsaw struggles or exhibits unusual behaviour, further inspection of the spark plug and connections may be needed.

Lastly, checking for any smoke or unusual sounds during operation is crucial. If excessive smoke or noise occurs, it may signify underlying issues that need addressing, such as fuel mixture problems or air filter clogs. Regular checks after spark plug replacement not only enhance chainsaw reliability but also contribute to long-term performance and safety.

| Testing Step | Description |

|---|---|

| Reconnect Spark Plug Lead | Ensure a secure connection before attempting to start the engine. |

| Run the Chainsaw | Observe the performance under load for smooth operation. |

| Check for Smoke or Noise | Look for any excessive smoke or unusual sounds during use. |

Tips for Prolonging Spark Plug Life

To prolong the life of a chainsaw spark plug, regular maintenance is key. Keeping the spark plug clean and free of debris helps prevent fouling, which can diminish its performance. Users should routinely inspect the spark plug and clean it using appropriate tools to maintain efficiency and ensure a consistent ignition process.

Using high-quality fuel is another effective way to extend the lifespan of a spark plug. Fuels with higher octane ratings can increase combustion efficiency, reducing the amount of carbon buildup on the spark plug. This practice not only enhances engine performance but also supports the overall health of the chainsaw, leading to less frequent replacements.

Lastly, always ensure that the spark plug is properly torqued to the specifications outlined in the chainsaw’s manual. An overly tight or loose spark plug can lead to damage or ineffective ignition, putting additional stress on the engine. Taking the time to follow these guidelines will help ensure reliable operation and longevity of the spark plug:

| Tip | Description |

|---|---|

| Regular Maintenance | Inspect and clean the spark plug to prevent fouling. |

| Use Quality Fuel | Utilise high-octane fuel to reduce carbon build-up. |

| Proper Torque | Ensure the spark plug is torqued to manufacturer specifications. |

Scheduling Regular Maintenance for Optimal Performance

Scheduling regular maintenance is vital for keeping a chainsaw in optimal working condition. Users should plan to inspect the spark plug every few months or after significant use, as this helps to identify wear and potential issues before they escalate. Keeping a record of maintenance tasks can also ensure timely checks and replacements, contributing to the chainsaw’s longevity.

In addition to spark plug inspections, users should consider other routine checks, such as examining the air filter and fuel system. A clean air filter enhances engine performance and reduces strain on the spark plug, while a properly functioning fuel system prevents fouling. Users who develop a comprehensive maintenance schedule will likely experience smoother operation and fewer unexpected breakdowns.

Creating reminders for maintenance tasks can be a simple yet effective strategy to maintain performance. Setting alerts on personal devices or using calendar reminders helps users stay on track with routine checks. By prioritising these actions, chainsaw users can ensure their tools remain reliable and efficient for all cutting tasks:

| Maintenance Task | Frequency |

|---|---|

| Inspect Spark Plug | Every few months or after heavy use |

| Check Air Filter | Every month |

| Examine Fuel System | Before long periods of use |

Conclusion

Replacing the spark plug in a chainsaw is crucial for maintaining optimal performance and ensuring the engine runs smoothly. By following a step-by-step guide, users can effectively troubleshoot common issues and reduce the risk of frustrating breakdowns. Regular maintenance checks and timely replacements not only extend the lifespan of the spark plug but also enhance overall chainsaw efficiency. Prioritising these tasks empowers users to keep their chainsaw in peak condition, ensuring reliable operation for all cutting needs.